Understanding Different Types of Screws and Their Applications

Screws are essential fastening elements utilized in a variety of industries and daily tasks. Although frequently disregarded, selecting the appropriate screw can greatly influence the strength, longevity, and effectiveness of your assembly. This guide thoroughly explores the different varieties of screws, their constructions, materials, and optimal application situations—providing all the necessary information in a single resource.

Introduction: The Mechanical Importance of Screws in Structural and Functional Assemblies

- Functionality: Screws transform rotational torque into axial force, enabling materials to be securely tightened with minimal effort.

- Versatility: They find applications in woodworking, metalworking, electronics, construction, automotive sectors, and home maintenance.

- Reliability: Choosing the right screw guarantees structural stability, resists loosening due to vibrations, and safeguards against material damage.

- Why it matters: Selecting an inappropriate screw can lead to joint failure, harm to materials, safety risks, and higher expenses from repairs or replacements.

Taxonomy of Screws: Typological Overview Based on Function and Application

Here are the main types of screws categorized by their design and intended use:

Wood Screws

- Coarse threads and tapered shafts designed to grip fibrous materials firmly.

- Typically have a smooth shank near the head for better wood clamping.

- Used in furniture, cabinetry, and structural timber.

Drywall Screws

- Feature a bugle-shaped head and fine threads for attaching drywall panels to wood or metal studs.

- Designed to minimize damage to the drywall paper surface.

- Usually black phosphate coated for corrosion resistance.

Machine Screws

- Uniform diameter with fine threads for use in tapped holes or with nuts.

- Made mostly from steel or stainless steel.

- Used in machinery, electronics, and metal assemblies.

Self-Drilling Screws

- Have a drill bit tip that can penetrate metal without pre-drilling.

- Ideal for metal-to-metal fastening like steel framing or roofing.

Sheet Metal Screws

- Sharp, pointed threads that cut through thin metals and plastics.

- Available in various head styles for different applications.

Concrete Screws

- Hardened and designed with high-tensile strength and coarse threads.

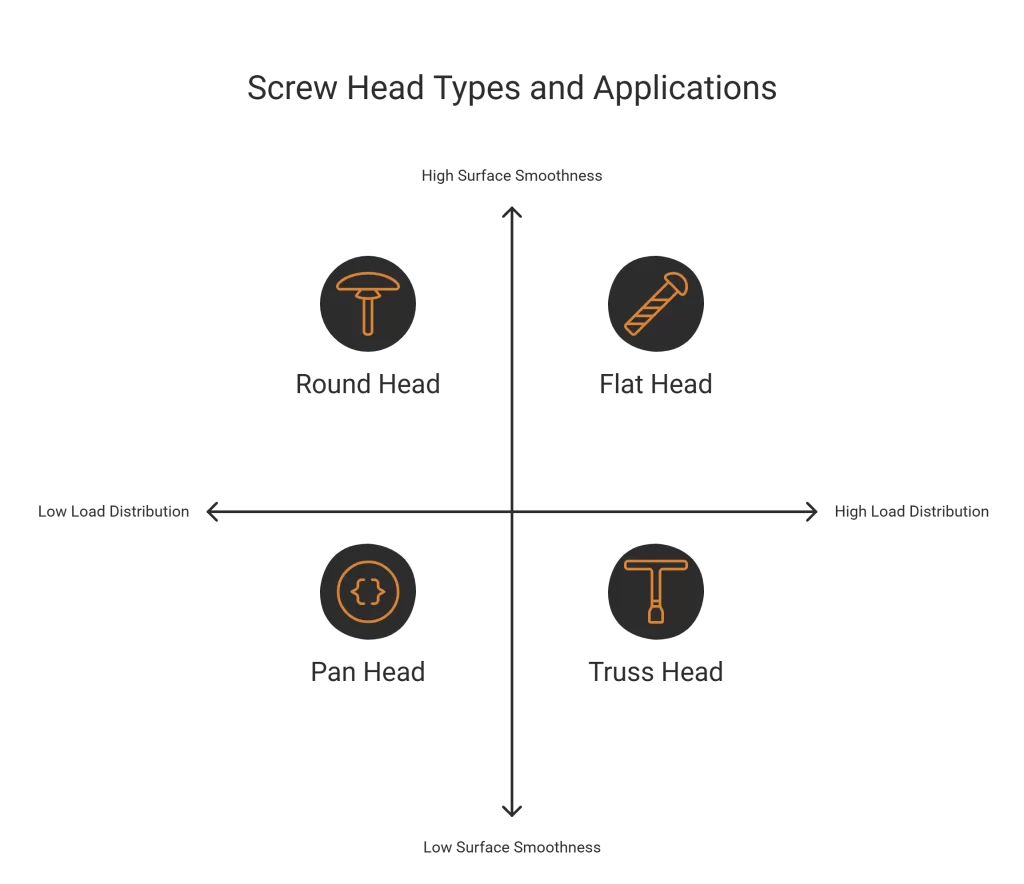

Screw Head Geometry: Functional Optimization for Tool Engagement and Load Distribution

Different screw heads are designed for specific purposes and installation tools:

- Flat Head (Countersunk)

- Designed to sit flush with or below the surface for a clean finish.

- Ideal for woodwork and finishing where surface smoothness matters.

- Pan Head

- Rounded top with a flat underside providing a wide bearing surface.

- Common in metal applications where the screw head remains exposed.

- Truss Head

- Wide and low-profile, spreading the load over a larger surface area.

- Suitable for soft materials like plastic or fabric.

- Hex Head

- Hexagonal shape designed for wrench or socket use.

- Enables high torque for heavy-duty fastening.

- Round Head

- Raised head for easy grip and removal; often decorative.

- Used in light-duty or exposed applications.

- Bugle Head

- Specifically engineered for drywall screws to spread the load and reduce surface damage.

- Flat Head (Countersunk)